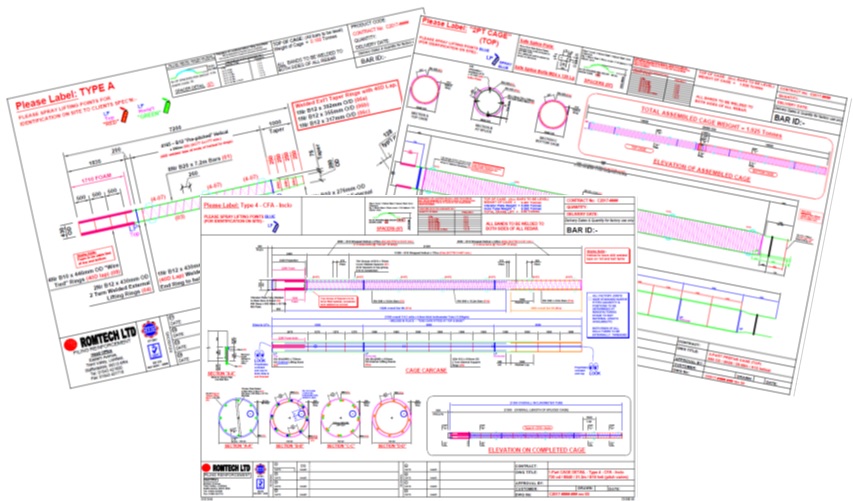

Detailing

ROMTECH’s AutoCad Detailing Facility Routinely:

Defines the exact cage format by producing a working drawing using customer contract documents. This usually takes place a few days prior to delivery of the relevant cage type and enables all parties to progress forward from the original contract rebar drawing/schedule stage.

The drawing will cover the scheduled main and transverse reinforcing bars and cage dimensons but can also include lifting joints, skid spacer locations, debonding isofoam, sonic coring/inclinometer pipes and couplers. Where clamped cage formers are used, the drawing will state the recommended torque settings.

ROMTECH

• works with the customer to obtain Clients approval of the ROMTECH drawing

• issues the pile cage drawings along with any necessary component drawings to ROMTECH’s Works for cage manufacture

• issues the cage drawing for factory welded cages to site for inspection of delivered consignments, for ongoing reference and for submission to the

Client

• offers a revision service for drawing updates

• maintains a long term database for completed drawings for use by customers and their Clients for the purpose of “as-built” records

• issues the cage drawing for site-assembled cages to site for the steelfixing and site inspection of completed cages